Glovebox stainless steel price on request

Shipping and delivery

- Free shipping for orders over CHF 150.00

- For orders under CHF 150.00 we charge a flat rate of CHF 50.00 for shipping

- Costs for shipping abroad: on request

Collection by the customer is not possible for logistical reasons.

Payment options

When paying by means of a payment method offered by PayPal, the payment is processed via the payment service provider PayPal.

If the payment method purchase on account is selected, the purchase price is due after the goods have been delivered and invoiced. In this case, the purchase price must be paid within 30 (thirty) days of receipt of the invoice without deduction, unless otherwise agreed.

For new customers without purchase references, we only allow ourselves to deliver the goods against advance payment.

Support

Do you have any questions? Do you need help?

We will be happy to help you find your product.or advise you.

Don't hesitate to call us:

Tel +41 32 618 00 11

Email: info@inertec.ch

Do you still have questions about the product?

To the contact form

Product description

Individual dimensions and design requests possible according to your wishes.

Request a noncommittal offer.

Call us: We would be happy to advise you personally to create an offer tailored to your requirements

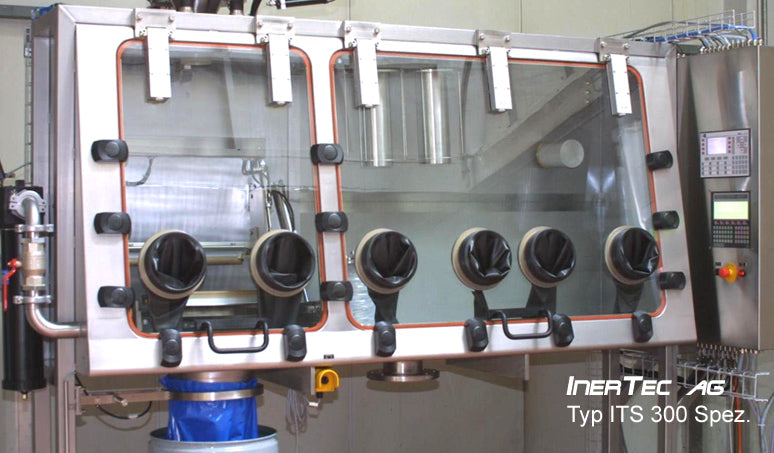

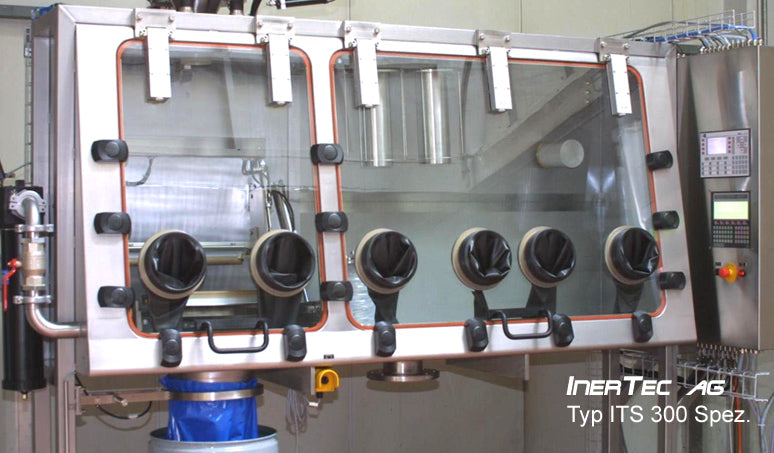

Workplace inert gas glove box system

- InerTec Glove-Box System for working under N2 / or Ar atmosphere

- With this system, the inert gas circuit is constantly circulated through the integrated gas cleaning with absorption filter

- The O2 / and H2O particles entering through diffusion are continuously absorbed, resulting in a residual contamination of < 1 ppm range

- The consumption of inert gas can practically be ignored

Typical applications

Universities and R & D Centers (research and development centers), chemistry, pharmaceuticals etc. suitable for:

- Assembly

- Sampling

- Welding work

- Semiconductor manufacturing

- Basic research

- Lithium battery production / OLED

- General handling for all O2 and H2O sensitive materials

particularities

- The ITS series systems are the result of years of optimization work. Due to the consistent use of high-quality components and the proven control, the interesting price-performance ratio could be achieved.

- The structural design of the base housing made of stainless steel allows practically unlimited expansion options.

- The gas-tight welded construction guarantees maximum tightness and stability.

- The front frame system with quick-release system at a defined fixed stop allows the windshield to be easily removed and reattached in just a few minutes.

- Optionally also with hinges

- The front frame seal guarantees the best values in terms of tightness in the over- and under-pressure working area.

This service-friendly concept is, among other things, to be seen as a decisive criterion compared to other systems

- The ITS Glove Box has proven, maintenance-free and user-friendly controls. The ergonomic and space-saving design allows the Glove Box to be easily integrated into a laboratory. All pipes and cabling are laid compactly. Glove

- Box is delivered fully operational and tested. This eliminates additional, often not insignificant, assembly costs.

service

- The box is designed so that it can be set up on a standard work table. All that is required for commissioning is the connections for gassing the box and the lock.

- The front unit, which is aligned at an upward angle of 100° to the rear, allows ergonomic work in both a standing and sitting position.

- The individual bushings are integrated into the rear wall, on the side wall or on the box roof at the customer's request.

cleaning

- Thanks to the raised radii in the corners, the working chamber is very easy to clean (free of dead space)

Basic box

- Description housing:

- Gas-tight welded housing made of stainless steel Box base with radii and externally integrated reinforcement frame to e.g. B. to place on vibration dampers.

- Surfaces inside and outside mill-finished or powder-coated

- Butt seams ground K 220,

- Surface treatments (see options)

- Material thickness: 2.0 mm

- Dimension: according to customer requirements

Version of insulator housing:

- Welded stainless steel housing

- Smooth surfaces in the work area

- Housing with ball corners on request for optimal cleaning

- Pane made of laminated safety glass

- Folding front window upwards with stainless steel window frame

- Pane secured with lock

- Oval glove bushings and gloves made of EPDM (optional)

- Disc seal made of EPDM for dead space-free sealing of the slide

- Automatic negative pressure control

- HEPA filter in the gas inlet and outlet

- HEPA push-push double filter

- Pressure display

lighting

- System workstation light 38 watts, in a removable housing, (powder-coated, ultramarine blue)

- Ensures optimal lighting of the workplace.

Front unit

- Foldable front window with stainless steel window frame (optional)

- Safety laminated glass pane (10mm) with detachable, two-part, screwed glove bushings made of hard metalized aluminum for best chemical resistance.

- Front frame design with quick-release frame on a defined fixed stop allows the front window to be dismantled and reassembled in just a few minutes.

- The static hose seal allows excellent sealing in both negative and positive pressure.

Gloves (pair)

- Butyl gloves size M

- L=850 mm, ø 196 mm or oval according to customer requirements, material thickness 0.6 mm

- Optionally also available in Neoprene, Hypalon, Viton or Latex, in sizes S and L

Media ducts on the side wall:

- Gas connection for N2 / Ar with shut-off ball valve and hose nozzle DN 06, thread 1/4€œ

- Thermostat to heat/cool reactor

- Cool cryostat to cooler

- Vacuum connection

- Water connection

- Electrical / power connection (e.g. agitator, magnetic stirrer, scales)

- PT-100 connection Lemo

- Dosing lines

- Or media implementation according to customer requirements

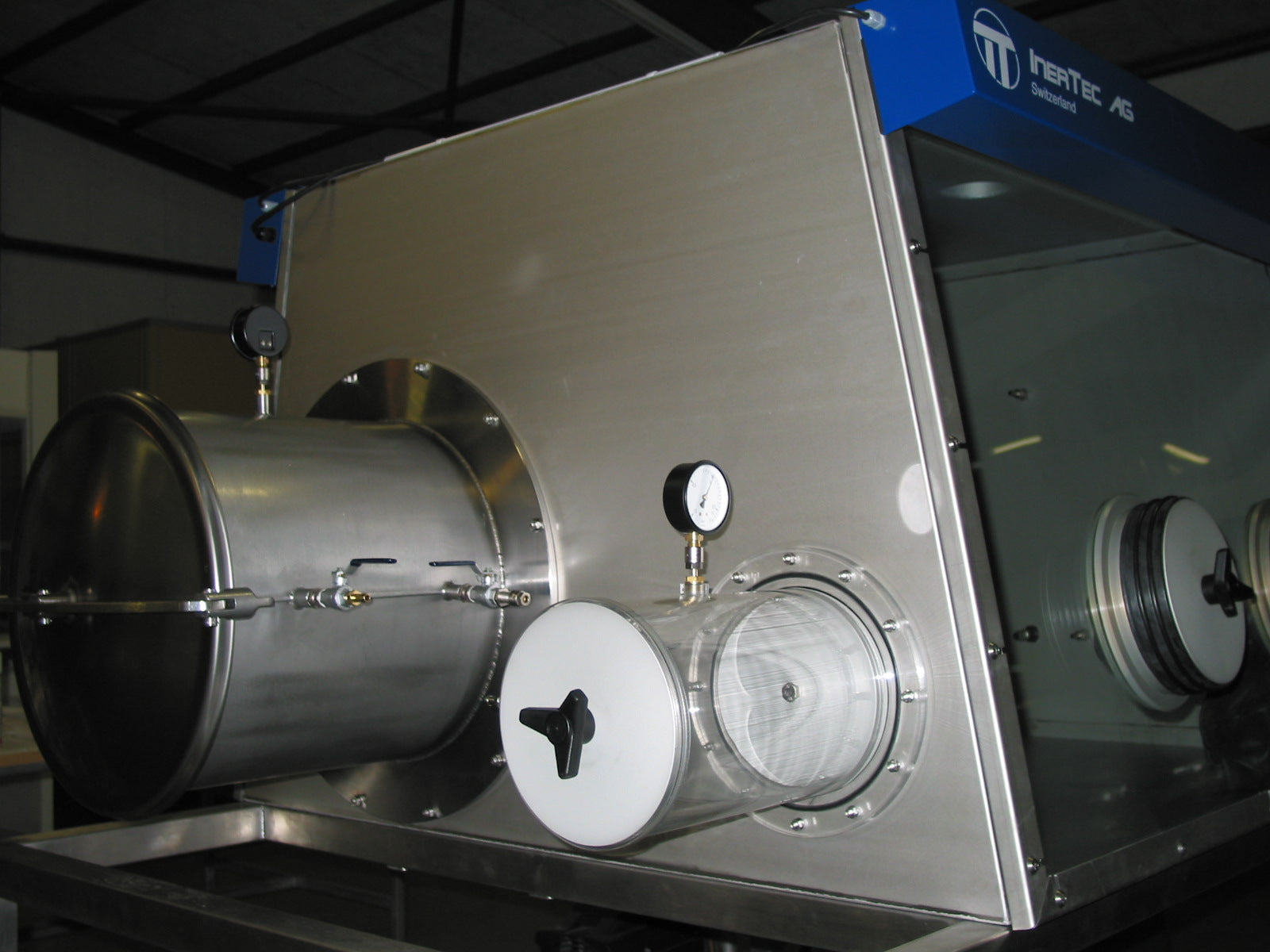

Transfer vacuum lock

- Allows material transfer without affecting the inerted atmosphere.

- Made of sturdy stainless steel including two ball valves DN 6 mm for gas supply and vacuum, pressure display.

- Easy-to-use inside and outside swing doors.

- Insulator lock made of stainless steel

- Manually or electrically locked swing doors inside and outside

- Doors made of transparent plastic, stainless steel or powder-coated sheet steel

- The transfer device works in constant negative pressure to the environment

- When the outside door is open, there is an air flow into the transfer device.

- When the inner door is open, there is an air flow towards the insulator.

- Air flow secured via filter

- Further vacuum locks made of acrylic glass and various service doors on request.

vacuum pump

- Membrane vacuum pumps (with filter protection) for evacuating the lock and pressure regulation of the working chamber, including oil mist filter.

Technical data:

- Flow rate 15/18 m3/60 Hz

- Final pressure < 3x10-2 mbar

- Motor power 370 W

- Oil filling: 850 ml

- Weight 22kg

- The DN 25 outlet connection is recommended to be connected to an exhaust system.

Gas cleaning

- Radial fan 230/240 V, for 22-fold air change.

- Stainless steel circulation pipes.

- Inlet and outlet flange connections KF-40 with

- O-ring seals connected.

- The input particle ultrafilter (EU 13) is a non-renewable fine dust or suspended matter filter made from compressed air and gases.

- The filter is mounted inside the glove box and can easily be replaced externally using the gloves without contamination.

- 1 adsorber unit (filling volume 8.6 kg) for removing O2 and H2O.

PLC control unit based on Siemens S7-200.

- Touch screen control panel with color display

- Process control for pressure regulation:

- Digital input of the upper and lower limit values of the desired working range in excess or negative pressure. Permanent status display.

- The working pressure of the Glove Box is controlled via the integrated automatic pressure control.

- The working pressure can be entered freely.

Automatic lock

- Automatic rinsing and evacuation process, guarantees “clean” material transfer into the working chamber.

- The factory default is 3 cycles.

- The flushing and evacuation process is signaled by an indicator light.

- Energy supply for all components included in delivery.

- Solenoid valves, 24 V, DC, easily accessible next to the adsorber unit.

- Regeneration (adsorber):

- The automatic regeneration (3-stage program) is started using a push button.

- The regeneration process is signaled by an indicator light.

O2 measuring device: type IT-TOS 1.0

- Digital display in PPM/V

- The maintenance-free trace oxygen analyzer with miniaturized amperometric limit current sensor has been specially developed for measuring low oxygen partial pressures. The use of TZP (polycrystalline tetragonal zirconia) as a solid oxygen ion conductor with improved electro-chemical and thermomechanical properties guarantees excellent measurement values.

- The device does not require a reference electrode, which would be used up over time.

- No increase in water vapor pressure due to the measurement.

- The sensor is selective for oxygen and requires no maintenance.

- Feed-through probe in KF 40 flange

- Large format (25 mm) LCD display of the O2 partial pressure in ppm.

- Display range: < 0.1 ppm €“ 200 ppm or 1 ppm €“ 2000 ppm

H2O analyzer: (optional )

- Al2O3 dew point transmitter, which guarantees reliable measurement of moisture content

- By using this device, the rigid, time-controlled regeneration cycles of the adsorbers are no longer necessary

- The extremely large dynamic measuring range of the aluminum oxide sensor is characterized by the shortest response times and long-term stability

- The microprocessor-supported device electronics deliver measured values without delay

- LCD display in 0C or ppm

- Input data using membrane keys

- Measuring range: 0.1 €“ 23,000 ppm.

- Temperature range: -100C to +700C

- Interface: RS-232

- Feed-through probe in KF 40 flange

Base frame

- Robust mobile base frame (welded construction) made of stainless steel with swivel castors and leveling feet. Allows easy insertion and alignment in the laboratory

Optional:

- Flushing control with pressure regulation

- Flushing control with pressure control and with data logger

- Gas cleaning with 1 adsorber

- Gas purification with 2 adsorbers: Second adsorber for continuous operation during regeneration

- Solvent adsorber can be switched on via bypass, activated carbon filter for the removal of solvent vapors. With DN 40 clamp screw connection including by-pass lock. The activated carbon cartridge used can be replaced very easily. Volume of activated carbon approx. 250g (other volume sizes on request)

- Recommended reserve bushings Positions can be determined by the customer KF-40 blind flange gas ball valve DN 6 with hose nozzle on both sides for hose I ø 8 mm

- Mini Transfer vacuum lock allows material transfer without affecting the inerted atmosphere. Made of sturdy stainless steel tube, inside  150 mm, length 400 mm, including two ball valves DN 6 mm for gas supply and vacuum, vacuum pressure gauge. Inside and outside doors with integrated seal.

- Power feedthrough: Gas-tight, screwed, power feedthrough with plug connection on both sides, 3-pole, 230V/50/60Hz.

- Mobile storage rack with 2 shelves, dimensions 700 x 300 mm, with 12 mm edge. Distance supports: height 200 mm each, with PTFE sliding feet.

- Inner lid for changing gloves

- Outer cover to close the glove openings. (To be used when the system is not in use for a long period of time in order to maintain the indoor atmosphere). Prevents diffusion through gloves

- For further options see “Glovbox stainless steel accessories”

Available downloads:

Get in touch with us

Questions about the product?

InerTec AG

Manufacturer for cleanroom technology

With our many years of experience, we implement cleanroom technology systems together with our partners. Customer requirements are at the forefront of project planning. Before implementation, we work out the optimum concept, always in close cooperation with our customers in a spirit of partnership.

For us, quality is the match between our products and services and the specified requirements.

Consulting

Our team of consultants and process engineers will provide you with professional support for your project.

Engineering

Your project is designed using the latest CAD systems and can be adapted effortlessly.

Planning

We plan and implement individual cleanrooms and expand existing cleanrooms in accordance with the required standard.

Realization

The components for your product are manufactured using state-of-the-art equipment

Frequently asked questions

Do you have any questions? Do you need help?

We would be happy to help you find your product or advise you.

How does the ordering process work?

Yes, we ship all over the world. Shipping costs will apply, and will be added at checkout. We run discounts and promotions all year, so stay tuned for exclusive deals.

What means of payment are available?

It depends on where you are. Orders processed here will take 5-7 business days to arrive. Overseas deliveries can take anywhere from 7-16 days. Delivery details will be provided in your confirmation email.

Are products also delivered outside Europe?

You can contact us through our contact page! We will be happy to assist you.

How long does shipping take?

Write content to answer to common questions your customers may have about your products, shipping policies..

I have special requirements, can the products also be customized?

Write content to answer to common questions your customers may have about your products, shipping policies..