Emission extraction Plus +

Shipping and delivery

- Free shipping for orders over CHF 150.00

- For orders under CHF 150.00 we charge a flat rate of CHF 50.00 for shipping

- Costs for shipping abroad: on request

Collection by the customer is not possible for logistical reasons.

Payment options

When paying by means of a payment method offered by PayPal, the payment is processed via the payment service provider PayPal.

If the payment method purchase on account is selected, the purchase price is due after the goods have been delivered and invoiced. In this case, the purchase price must be paid within 30 (thirty) days of receipt of the invoice without deduction, unless otherwise agreed.

For new customers without purchase references, we only allow ourselves to deliver the goods against advance payment.

Support

Do you have any questions? Do you need help?

We will be happy to help you find your product.or advise you.

Don't hesitate to call us:

Tel +41 32 618 00 11

Email: info@inertec.ch

Do you still have questions about the product?

To the contact form

Product description

Individual dimensions and design requests possible according to your wishes.

Request a noncommittal offer.

Call us: We would be happy to advise you personally to create an offer tailored to your requirements.

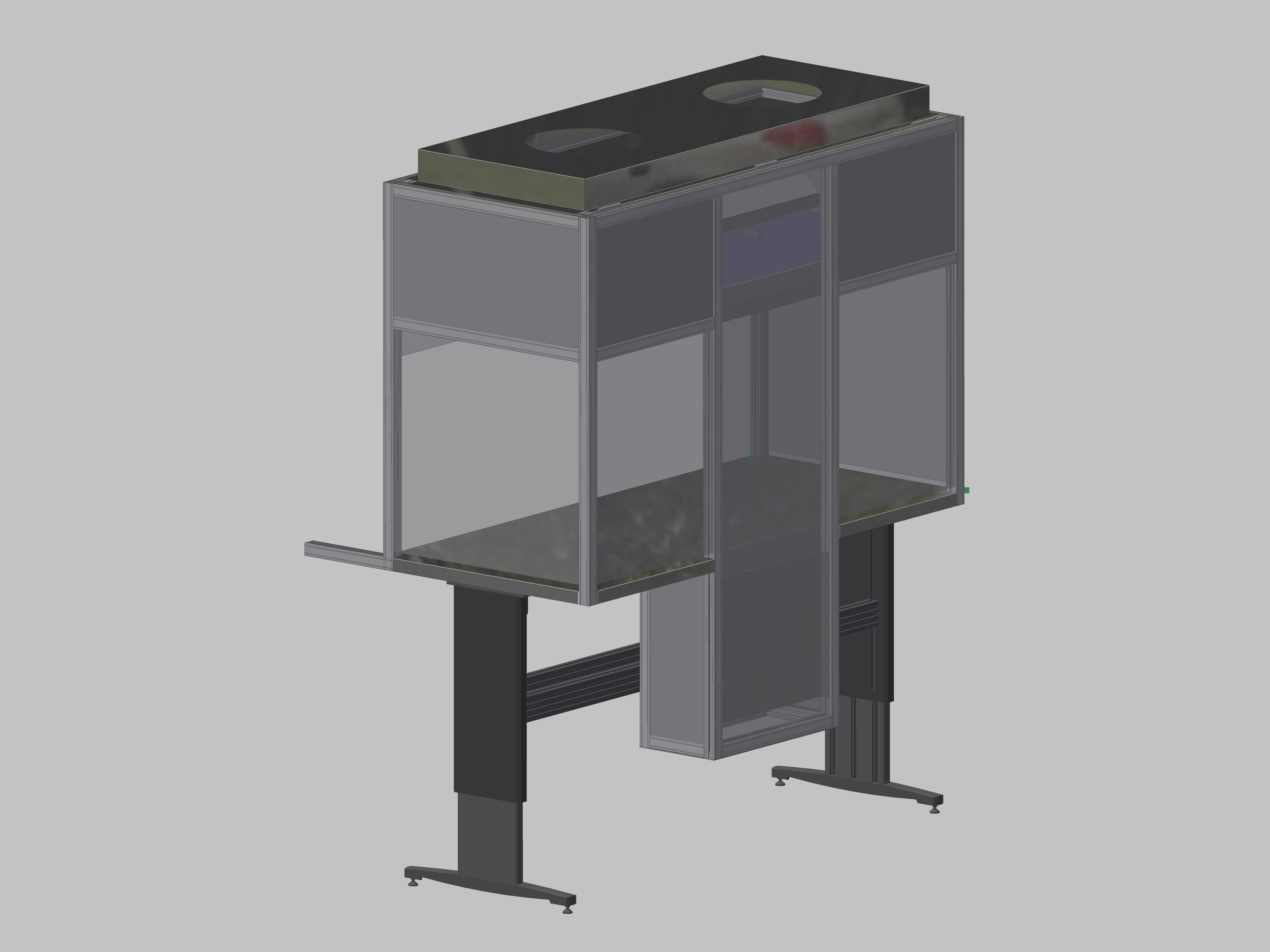

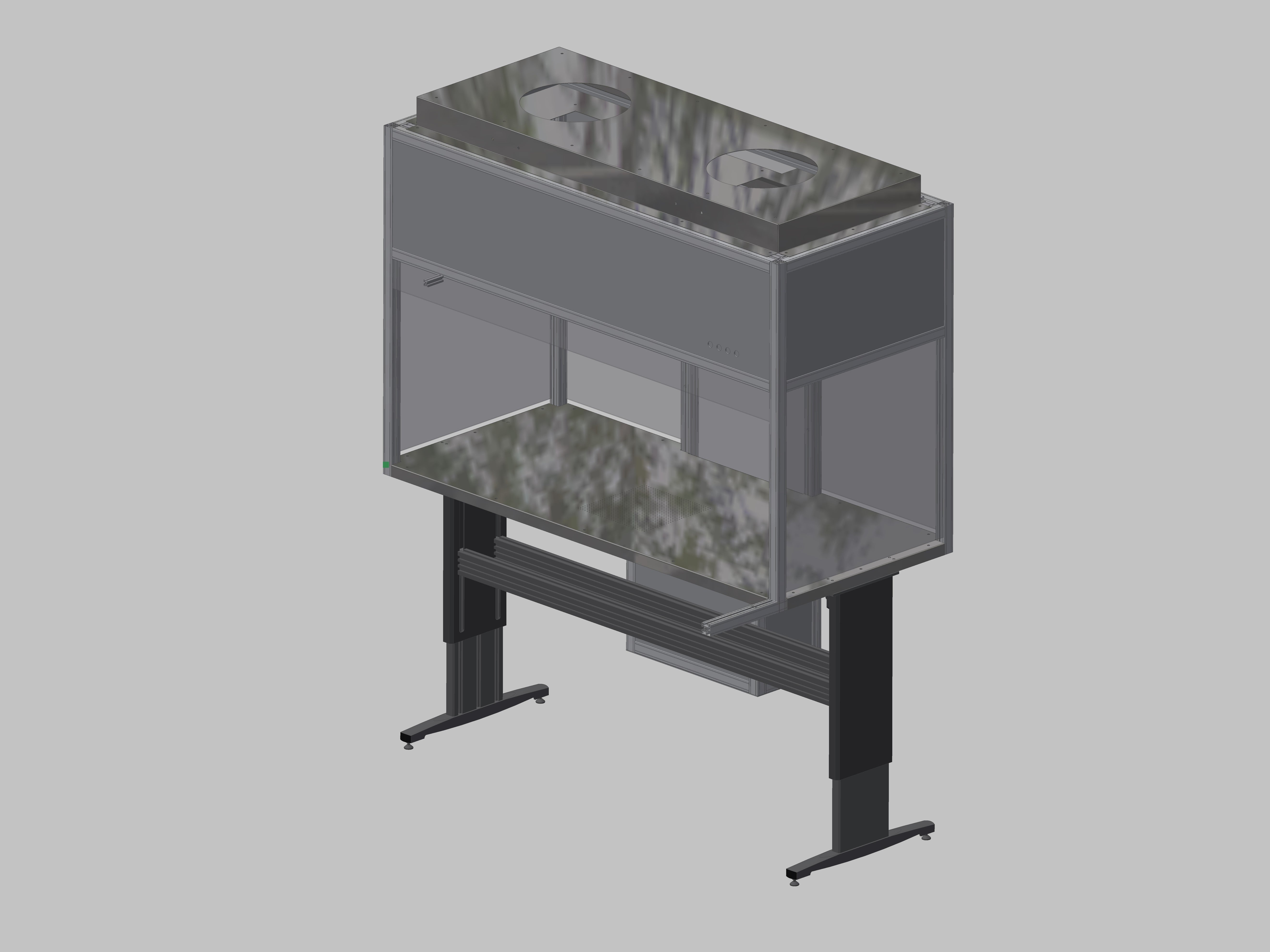

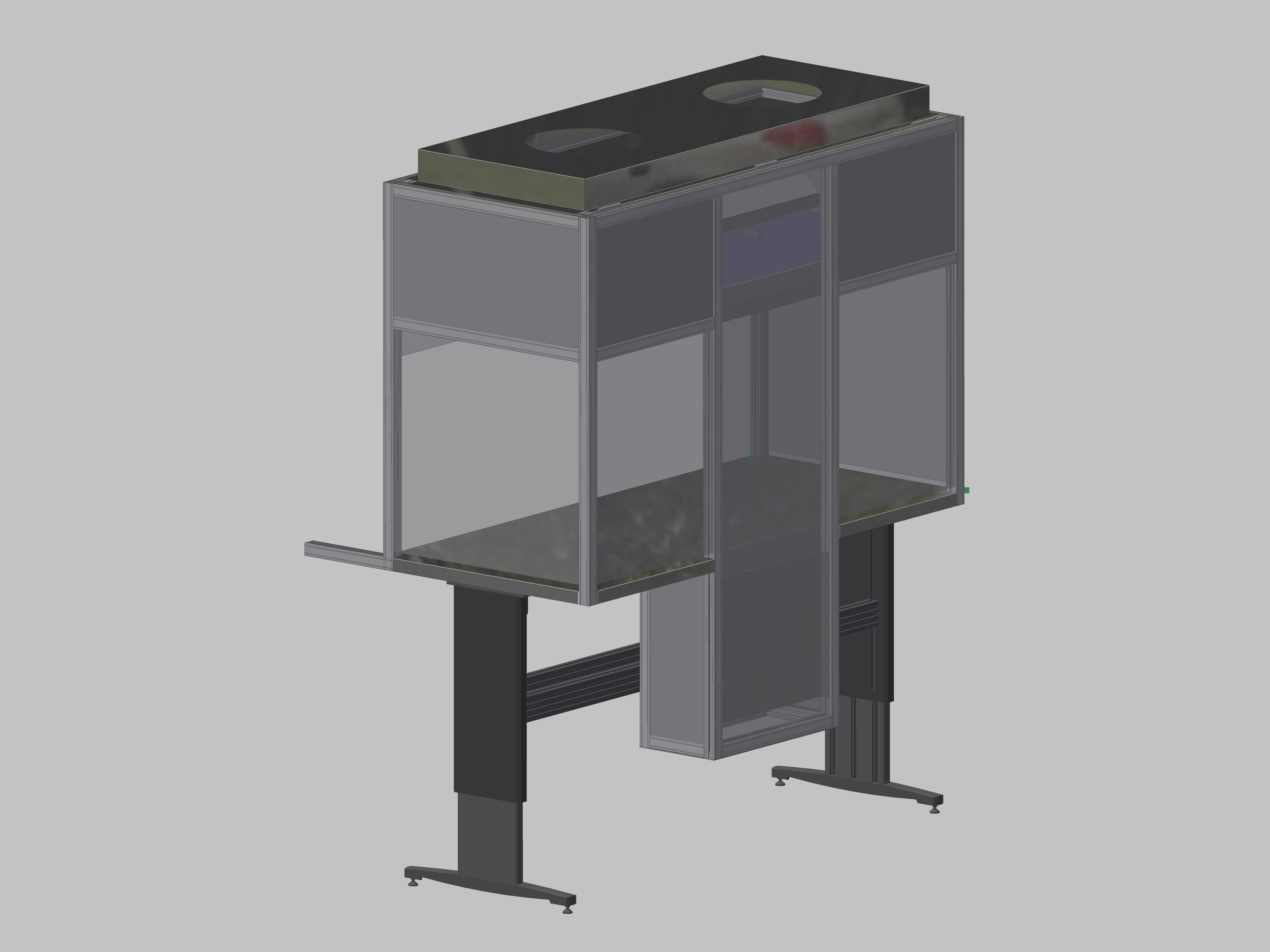

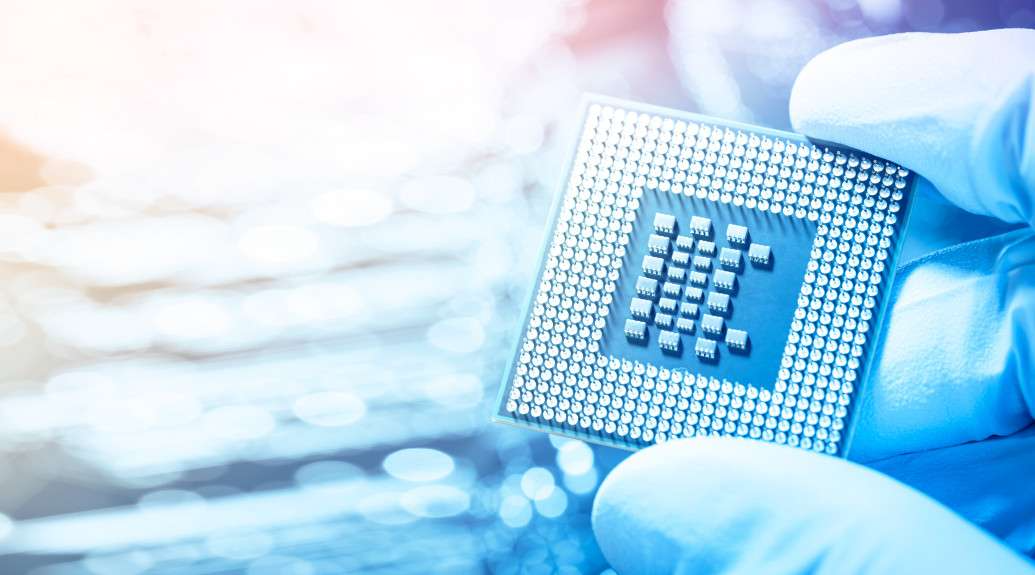

Emission extraction Plus + clean room workstation ISO5

technical description

Emission extraction as a personal protection system Molecular filter system: eliminates a wide range of pollutants that endanger people such as: solvents, acid gases, ozone and others combined with a clean room workplace: Laminar flow ISO 5 / 14644-1.

All systems can be manufactured individually according to customer requirements. This means we are not tied to any fixed dimensions or expansion requests. This modular series offers the user the following striking advantages at no additional cost:

particularities

- The new systems can be designed flexibly in terms of dimensions and can be adapted to individual customer needs

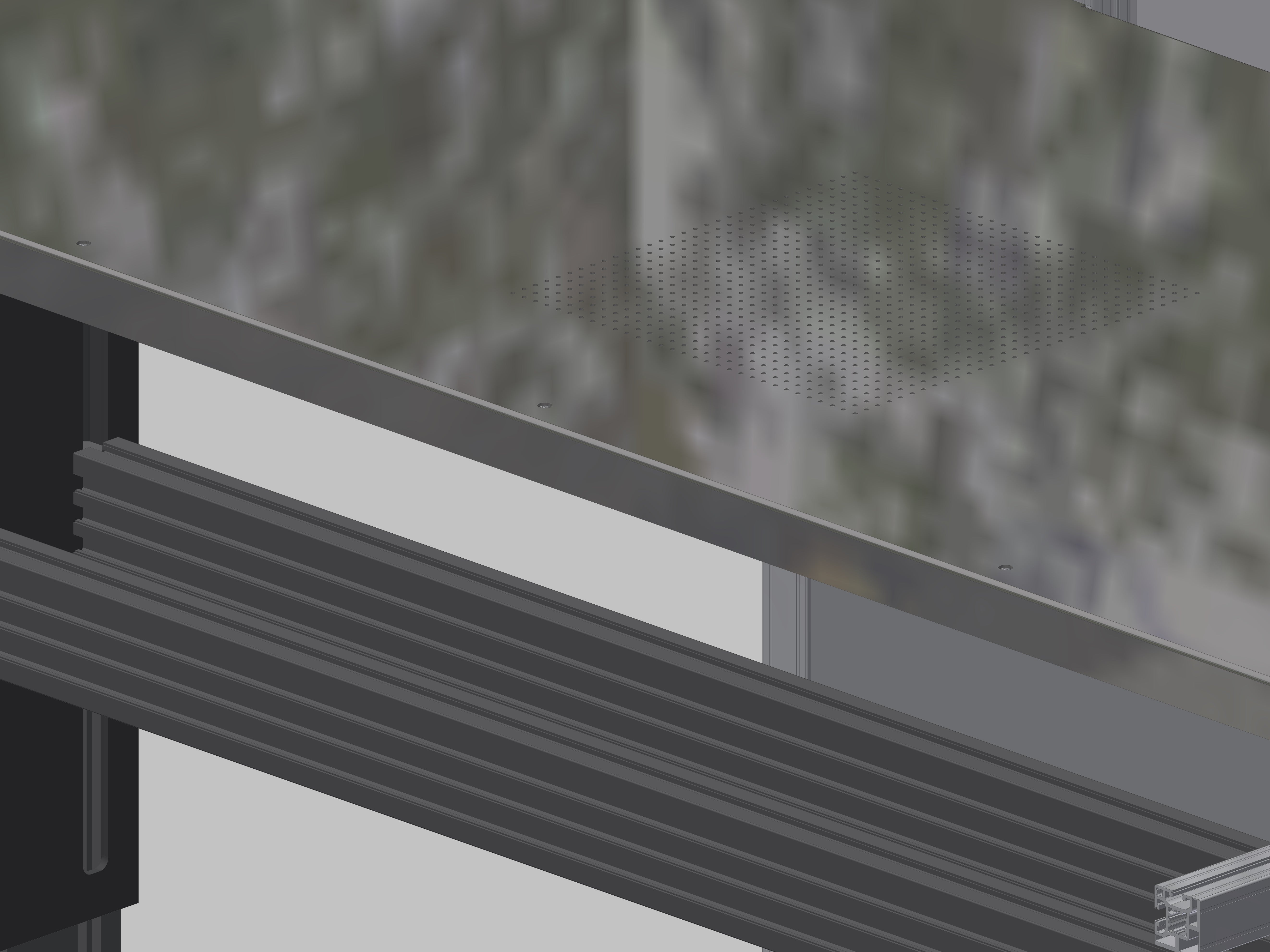

- The module is made of aluminum construction in which the high-performance blower is located

Vibration damper is constructed

Technology

- Night reduction / weekend reduction 3 language display D / F / E (energy saving): optional

- Monitoring the flow velocity (digital display)

- Filter clogging indicator: optional

- No interference with the operator due to air flow

- Whisper-quiet operation 43 dB(A) at 0.20m/s

(with the quietest fan on the market) - Individual dimensions

- Available with brightness-controlled high-performance LED on request

Additional benefit

When using the VarioClean Flow systems, a large amount of air is circulated and thus also cleaned of airborne viruses and bacteria. This massively improves the air quality in the surrounding area.

There are no limits to your individual wishes. Please contact us!

Optimal planning and design guarantees years of successful quality

Purpose

The unit is ideal for demarcating work areas in a cleanroom manner. The unit is used to filter out particles or germs from the ambient air, to remove solvents from the ambient air and thus guarantees a clean room atmosphere with personal protection. The modular system design means the device can be used flexibly.

Purity class

The Laminar Flow Unit works on the principle of laminar displacement flow with vertical airflow. It meets the requirements of purity class 5 according to DIN ISO 14644-1, which corresponds to purity class 100 according to US-FED-STD 209e.

Pre-filter

The ambient air is pre-filtered using an easily replaceable pre-filter of filter class G4. The pre-filter is designed for large volume flows and long filter life.

Fine filter

The particles are separated using a high-performance class H14 suspended matter filter. The separation efficiency of this filter is 99.995% according to EN 1822. The maintenance-friendly device design makes it easy and cost-effective to replace the filter directly at the installation site.

Molecular/activated carbon filter

- C1 against odors from offices, laboratories, hospitals, halls, kitchens. Against solvent vapors, ozone, exhaust odors and general hydrocarbon compounds

- C3 generally against acid gases, mercaptans and thiols, against odors from sewage treatment plants, putrefaction

- C5 generally against alkaline gases such as ammonia and amines, against odors from animal husbandry and slaughterhouses.

- C9 suitable for air filtration at high humidity

- CX for specific applications (formaldehyde fumes, mercury fumes, etc

fan

The airflow is generated via high-performance fan modules with energy-saving motors. The wheels are finely balanced statically and dynamically. The compact module housings are made of aluminum sheet

Control with automatic speed control

The desired air speeds can be set manually using a multifunctional display with plain text display.

With the automatic speed control, the air speed is automatically kept constant even when filter resistance increases (increasing filter contamination). For this purpose, the air speed at the filter outlet is constantly measured using a precise flow probe and the engine speed is adjusted accordingly.

Other useful functions are integrated into the control, such as a timer function for any day/night switching to save energy, language switching to 3 languages, etc.

frame frame

The Laminar Flow Unit is made of aluminum construction.

Device dimensions

External dimensions W x D x H (mm): 1000, 1250, 1500, 1750, 2000, 2250 and 2500 x 600 x 1950 , available in any dimension for an additional charge

certificate

CE conformity

Available downloads:

Get in touch with us

Questions about the product?

InerTec AG

Manufacturer for cleanroom technology

With our many years of experience, we implement cleanroom technology systems together with our partners. Customer requirements are at the forefront of project planning. Before implementation, we work out the optimum concept, always in close cooperation with our customers in a spirit of partnership.

For us, quality is the match between our products and services and the specified requirements.

Consulting

Our team of consultants and process engineers will provide you with professional support for your project.

Engineering

Your project is designed using the latest CAD systems and can be adapted effortlessly.

Planning

We plan and implement individual cleanrooms and expand existing cleanrooms in accordance with the required standard.

Realization

The components for your product are manufactured using state-of-the-art equipment

Frequently asked questions

Do you have any questions? Do you need help?

We would be happy to help you find your product or advise you.

How does the ordering process work?

Yes, we ship all over the world. Shipping costs will apply, and will be added at checkout. We run discounts and promotions all year, so stay tuned for exclusive deals.

What means of payment are available?

It depends on where you are. Orders processed here will take 5-7 business days to arrive. Overseas deliveries can take anywhere from 7-16 days. Delivery details will be provided in your confirmation email.

Are products also delivered outside Europe?

You can contact us through our contact page! We will be happy to assist you.

How long does shipping take?

Write content to answer to common questions your customers may have about your products, shipping policies..

I have special requirements, can the products also be customized?

Write content to answer to common questions your customers may have about your products, shipping policies..